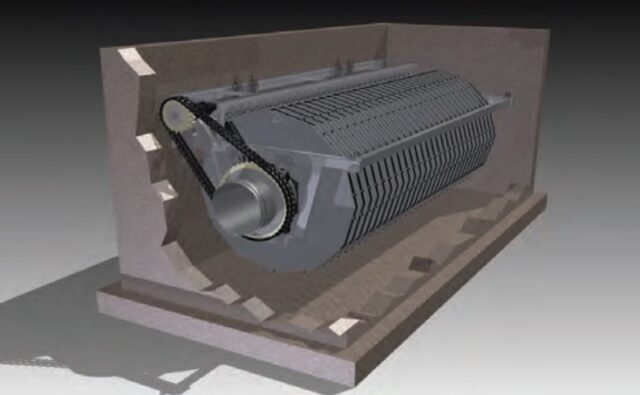

Disc Cloth Filter

The Disc Cloth Filter is made up of a drum or alternatively of filter discs mounted on a central hollow shaft. The filtration is done by gravity with an idle machine and uses the level difference between the input and output of the machine. The discs (or the drum) run completely immersed in the water to be treated.

During the filtration phase, the solids are held back by the special polstoff cloth. The minimum water level in the tank containing the filter is controlled by a weir placed on the side of the clean water outlet. With the increase of deposit of solids on the cloth, the hydraulic resistance increases in passing and therefore the difference between the levels of entry and exit.

When a difference of 15 ÷ 20 cm between these levels is reached, it automatically activates the cleaning process of the cloth.

To clean the cloth which is necessary to restore its filtering capacity, the discs (or drum) are rotated slowly. The solids are removed as a result of the backwash passage through the cloth, the water already filtered by a suction pump; this pump is connected to special suction nozzles, which by adhering to the walls of each disc or drum causes the free fiber of the cloth filter to stretch facilitating the release of the sludge particles retained therein.

The contact of the suction nozzle with the cloth filter generates the recompression of the free fibers and the consequent formation of an even filtration panel.

The cloth filter of the drum or disc filters is made of polstoff free fibers (fiber length from 10 to 12 mm and a diameter of 13 to 27 µ fastened to a large weave fabric that serves as support). The type of filtration obtained is comparable to the deep filtration of sand filters and not the surface filtration of the monofilament cloth filters.

Features:

- Depth filtration, similar to sand, for high solids load

- Filtration from outside to inside, backwash from inside to outside the discs

- Discs are completely submerged

- No chemical dosing, no tiny nozzles or small holes to be cleaned

- Free Fibre cloth

- Low installed power

- Gravity filtration

- SS 304 filter frame

EUROTECK is always ready to help you in keeping your plant compliant in any situation. For inquiry, mail us at info@euroteckindia.com | Call us at: +91 96876 93899