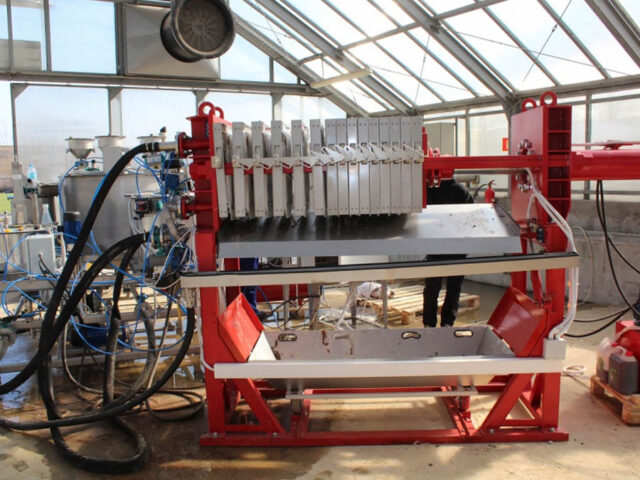

Chamber Membrane Filter-Press

These Chamber Membrane Filter Presses are used in the following cases:

- when maximum separation of phases is required

- when a filtrate of high purity is required

- when maximum cake moisture content is required

- for cost effective cake washing

- when high pressure is required for slurry separation

Description

Standard industries that use filter presses:

- Metallurgy (slurries of non-ferrous metal ore concentrates, iron ore concentrates, wet-cleaning oven gases, neutralized wastewater of etching stretches, galvanic effluent)

- Food industry (first saturation sugar juice, melt liquor of raw cane sugar, sunflower oil, ?, wine, juice)

- Chemical industry (titanium dioxide slurry, zeolite slurry, catalyst production slurries, silica white slurry, liquid glass)

- Cement industry (sludge from wet method cement production)

- Kaolin, ceramics, porcelain production (clay and kaolin slurries)

- Coal industry (sludge flotation)

- Industrial wastewaters (industrial rainwater, clarifier purging water on power plants, wastewater after regenerative air heater purging, wet ash removal, flushing wastewater, graphite containing slurries)

- Municipal wastewater

Operating Principle

The operation cycle with the filter plates clamping. The inner voids of plates are joined in the combined chamber space. When reaching a certain pressure value (which ensures the chamber space seal), the external pump feeds slurry into the filter press. This slurry gradually fills the filter press and due to the feed pump pressure , the liquid phase passes through the filter cloth and flows out of the filter press via the internal canal system. The cloth collects a layer of cake, with the thickness depending on the quality of the slurry supplied. This process takes place until the void is completely filled with the cake after which the slurry feed stops.

After filtering the cake in the chamber, it can be further processed to obtain additional effects with washing and drying. During washing the washing fluid is fed into the filter press. This expels the main filtrate from the cake. Washing can be done in several stages along with separation of the wash filtrate by concentration and discharging of the weakest portions for the first stages of the next cycle. Also, washing can be performed with several fluids. Washing is achieved by supplying washing liquids into discharge line from one side of the filter press. This provides conditions for uniform washing of the whole cake area. Washing is very effective in applications that require the maximum phase separation. Multilevel washing achieves good results with the lowest cost in washing fluid.

During the drying process, compressed air passes through the cake in the press, to decrease the cake humidity. As with the washing liquid, air is supplied into the filtrate discharging line from one side of the filter press to ensure uniform drying. Drying is done to reduce the moisture content in the cake for reduction of subsequent heat treatment costs, ensuring the transportation conditions of dried cake or to achieve maximum phase separation in cases when cake washing is impossible.

After filtering and processing, washed and dried cake is discharged from the filter press – the clamping plate is moved to the end position, followed by gaps appearing between the filter plates with the width greater than the cake thickness. Pressed by their own weight, cake fall out through the openings into the receiving bunker or on the removal device.

Advantages

Technical effects of Eurotek chamber-membrane filter press

| METRIC | METHOD TO ACHIEVE IT |

| High purity of filtrate |

|

| Minimum cake moisture |

|

| Low amount of initial liquid in the cake |

|

| Minimum filtrate dilution with the washing filtrate |

|

| Low air consumption for drying |

|

| Low consumption of washing liquid |

|

| Filtration capacity |

|

| Low power consumption |

|

| Easy maintenance |

|

| Long service life of filter clothes |

|

| Simple cake unloading |

|

| Simple filtrate removal |

|

| Separation of working fluids |

|

| Adaptive sequence diagram |

|

Automation

Eurotek filter presses are equipped with a variety of control and measurement instrumentation and a control system with an industrial controller. When the press is in operation, the control system manages the mechanical movements of different components, process operations and other processes related to them.

The automation level of Eurotek filter press is selected depending on the filter press type and size, its purpose, operating frequenc. It can be changed from completely mechanical to fully automated systems.

Characteristics

Technical specifications

| Parameter | Value |

| Filtration area, m2 | 1…1000 |

| Cake thickness, mm | 15…60 |

| Plate dimensions, mm x mm | 200 x 200 … 2000 x 2000 |

| Operating pressure, bar | up to 16 |

| Operational temperature, °С | 10 – 85 (0 – + 105) |

Variants

- Plate pack – chamber type, mixed, completely membranous.

- Plate suspension – overhead, side-bar

- Plate clamping – hydraulic, electro-mechanical, mechanical

- Plate separation – by sections, one by one, manually

- Pipe material – stainless steel, molybdenum steel, polypropylene, titanium

- Regeneration – portable high-pressure wash, automatic unit, chemical

- Valves – with pneumatic drive, with electric drive, manual

- Valve system – for all operations