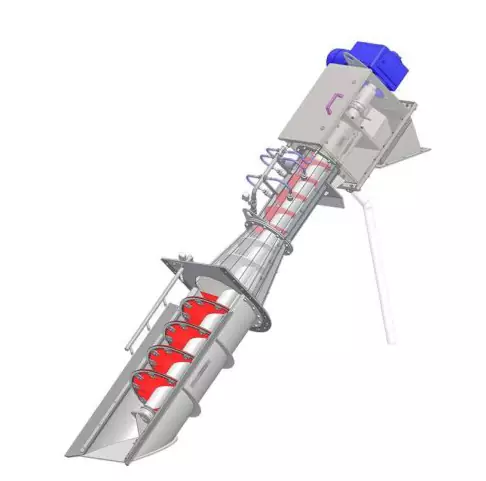

Screw Screen is a space-saving and proficient equipment for the partition of little and medium waste from industrial and municipal wastewater. Screw screens are dependable and utilitarian hardware for mechanical wastewater treatment with an incorporated framework for screenings washing and pressing.

Scope of Application of Screw Screens

- Municipal wastewater treatment

- Paper and Pulp industry

- Meat processing industry

- Vegetable and fruit processing plants

- Food industry

Features:

- The primary element of the screw screen is its usefulness. It isolates medium and little waste from municipal and industrial wastewater, at that point performs washing, pressing and transportation of the screenings to the garbage removal tank.

- An opened or punctured sifter is introduced at the lower part of the screen. As the wastewater goes through the strainer, the waste is held on the separating surface. The screw is furnished with a brush to clean the strainer in the filtration region. In the upper piece of the screen, there are territories for the screenings washing and pressing.

- Because of the coordinated screenings washing capacity, natural mixtures stay in the wastewater, which adds to the biological treatment measure.

- The shaftless screw prevents blockage, obstructing or sticking of the screen, in any event, when working with stringy materials.

- The utilization of a punctured sifter with little openings takes care of the issue of holding even difficult-to-get impurities, like hair.

- The screen can be outfitted with a gadget for dumping washed and dewatered squander into polyethylene packs, which isn’t just incredibly helpful for additional transportation of waste, yet in addition, forestalls the spread of odors.

- The design solves the issues related with the activity of a huge piece of the extra hardware for wastewater treatment, for example, there are no mind-boggling systems and parts that require consistent and work concentrated support.

- RVO screw screen can be effortlessly coordinated into the current complex of treatment offices and synchronized with different sorts of equipment.

- The screens are intended for use in wastewater with pH = 6.5÷8.5.

The durability of the Screw Screens:

-

- All work is finished by the screw, so there is no critical number of rotating parts. This increases the reliability and durability of the screen.

- The screw is made of wear-safe carbon steel, and a self-cleaning strong brush is introduced nearby the channel sifter.

- The utilization of stainless steel (AISI 304, AISI 316) in the unit gives its strength, which is vital for work in an aggressive wastewater climate.

EUROTECK is always ready to help you in keeping your plant compliant in any situation. For inquiry, mail us at marketing@euroteckindia.com | Call us at: +91 96876 93899